Pipedream

Here I am with Pipedream.

Pipedream is a robot that was designed to assist in decommissioning a couple of buildings at the Portsmouth Ohio Gaseous Diffusion Plant. From 1954 to 2001, this facility produced uranium for the United States' nuclear weapons program. One building had already been dismantled at the start of this project but two more remained. Inside of them were miles of pipes where uranium hexafluoride was moved around through successive stages of large chambers where the U235 uranium Hexafluoride diffused slightly faster than U238. U235 was used for the nuclear weapons program while U238 was used for other purposes. After years of use, the pipes developed deposits of uranium. Part of decommisioning was to determine where these deposits were. If there was lower than a certian threshold of uranium, a section of pipe could be cut out and buried on site. If the threshold was crossed, the pipe needed to be cleaned, which was expensive and dangerous for humans to do. Prior to using pipedream, workers had been doing a time-consuming and expensive of measuring the radiation produced by deposits by holding a radiation detector against the outside of the pipes for several minutes then moving on to a new location. A measurement was taken at several places around the pipe and every foot or so if I recall correctly. Because of the amount of piping in these buildings, this was a very labor intensive process.

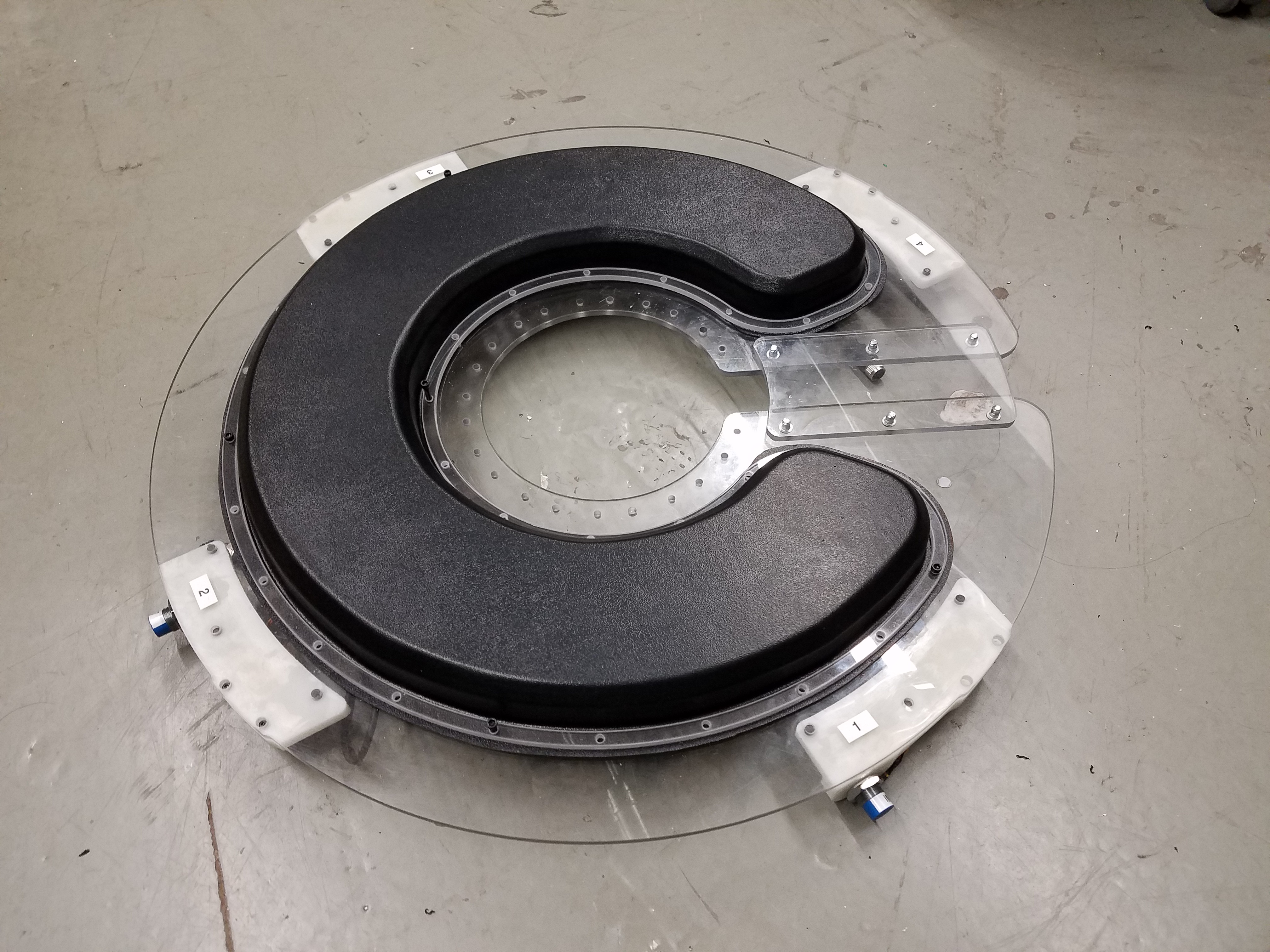

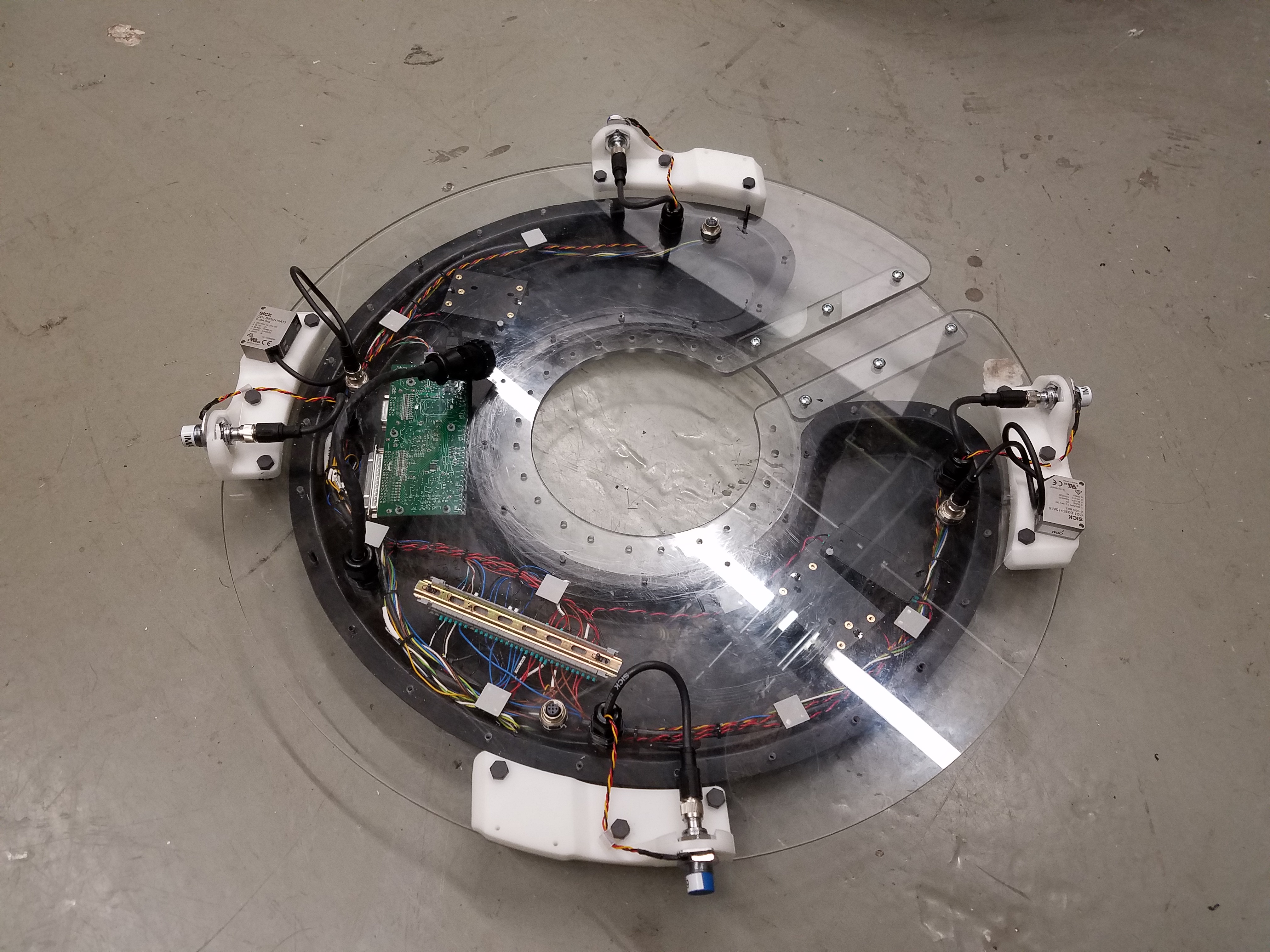

Pipedream sought to change that by measuring the radiation from within the pipes. Our team was told that the deposits would be hard coatings on the inside of the pipes and we needed to determine if the thickness was greater than 0.6mm thick. We approached this by using a pair of sensors. The first was a structured light rangefinder that could determine the distance to the surface of the deposit extremely accurately. The other sensor was an inductive sensor that could determine the distance to the underlying pipe. By comparing the two, we could determine the thickness of the coating. Complicating our efforts was the assumption that there woud be hydrofluoric acid within the pipes, which is produced when uranium hexafluoride comes into contact with water in the air. Hydrofluoric acid is pretty nasty stuff so we had to design the robot to resist its effects. Pipedream was designed with a rotating disk with four sensors located around its perimeter. As they rotated, the robot recorded the orientation of the disk and the readings of the sensors. In a post-process, we could create a map of where deposits were located and how thick they were.

When the robot was finished, we took it to the Portsmouth facility and put it into a pipe. While the robot worked as intended, the initial premise that we had been given that the deposits were hard shells proved to be incorrect. The deposits were more like snow that fell on a very cold day and were light and fluffy. This lead to wildly inaccurate estimates of how much uranium was contained within the pipes. Because of that, this robot was scrapped and a new robot was designed called Radpiper, which used two disks of lead with a radiation sensor in between. This gave a map of how much uranium was in the pipes but not specifically whether it was on the top, bottom, or sides. Ultimately this was good enough because the facility only wanted to know what sections needed to be cut out for further cleaning.

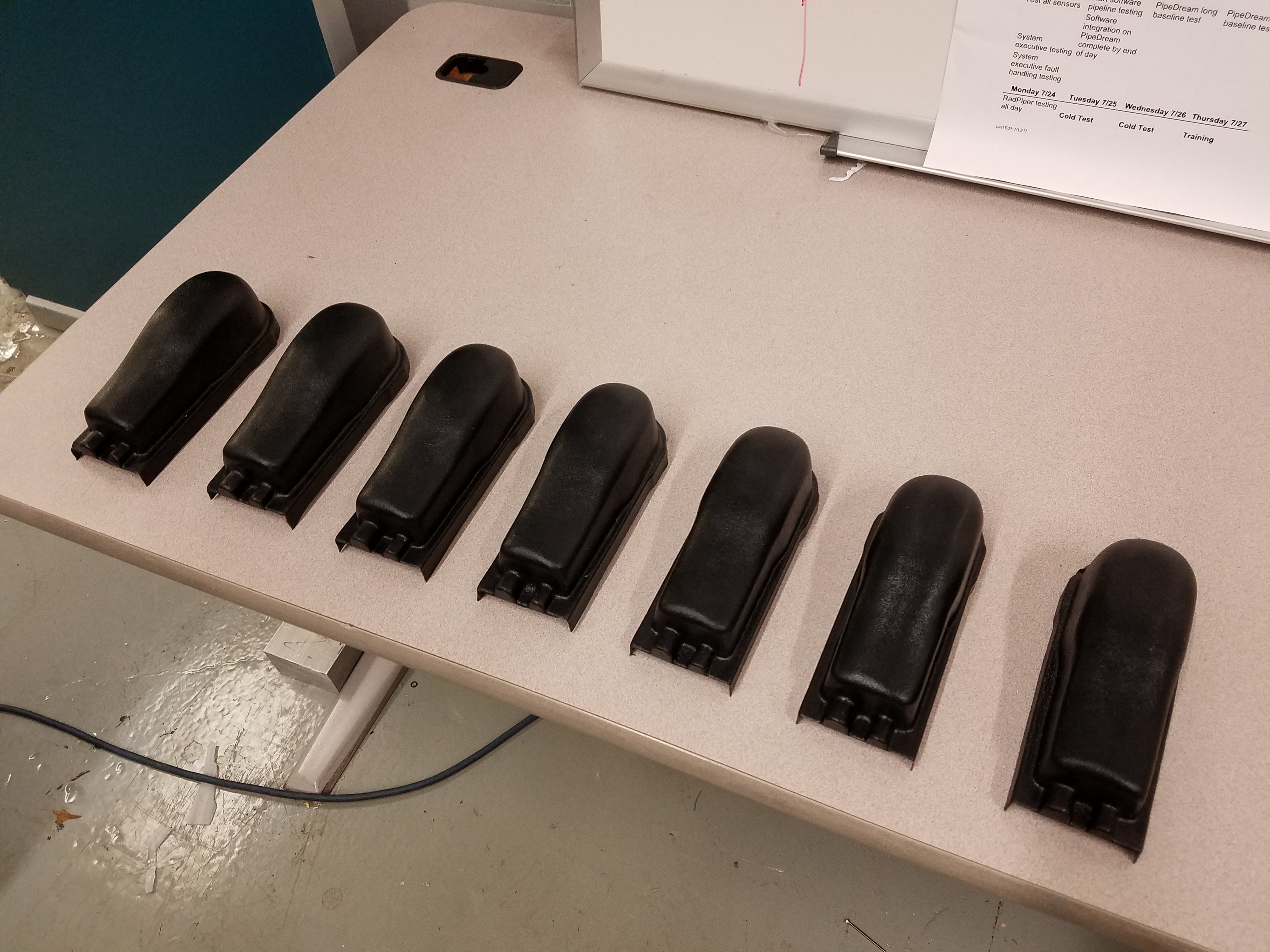

I knew how to operate a vacuum former so I was in charge of making all of the protective covers.

I designed the spinner disk in Solidworks, assembled it, and wired it up.

Here is a shot of the other side.

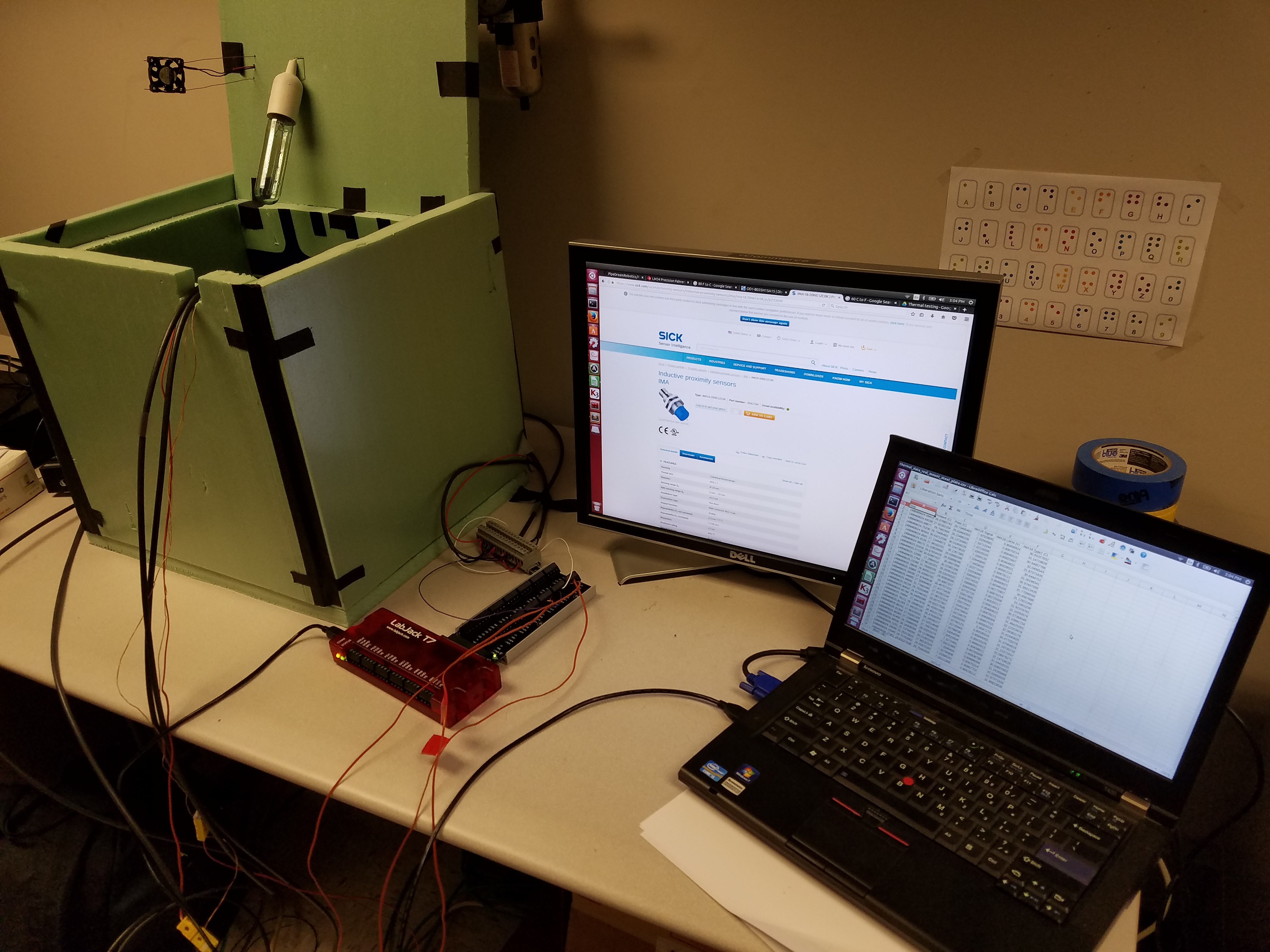

Because of the extremely small deposit thicknesses that we were meant to detect, we needed to know how the sensors behaved at different temperatures. The interior temperature of the pipes could vary wildly depending on time of day and time of year. I designed a simple thermal chamber and its associated testing proceedure. We also tested in a room that could drop the temperature as well.